Products | Rock Splitters | C20 J

Darda

Rock Splitters

make the

difference

Small carriers

Best power-to-weight ratio

Low vibration and dust almost noiseless

Economical and safe

Accurate splitting

Can be used under water

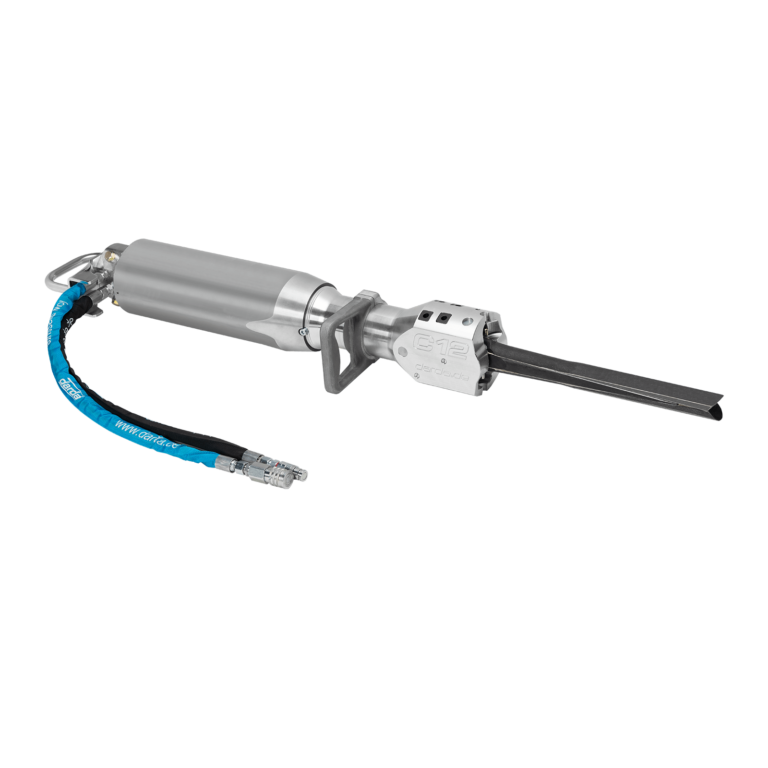

C20 J – machine

guided splitting

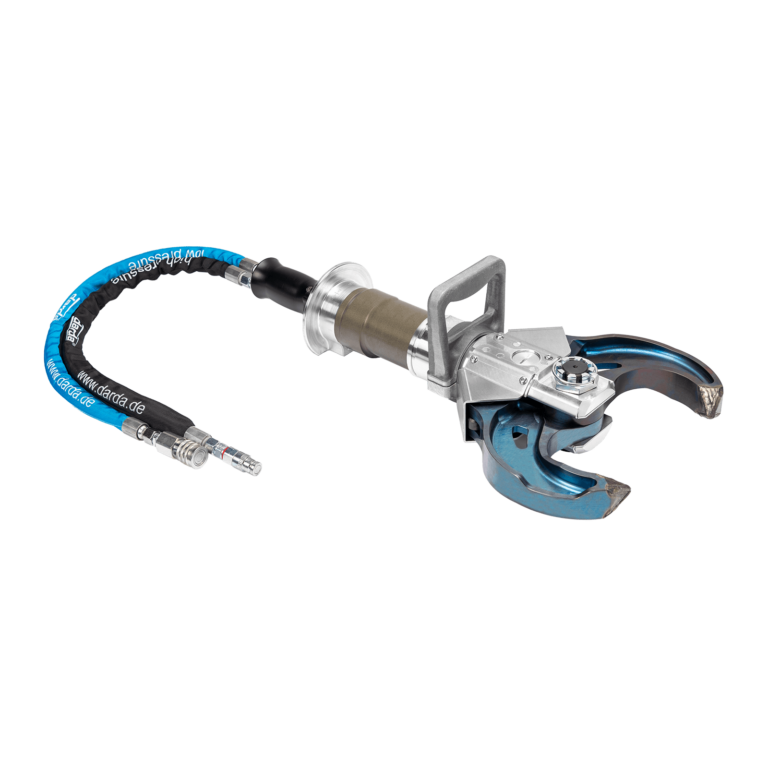

The Rock Splitter is the solution especially in urban and sensitive areas, because there is almost no noise and vibration, as well as flying rock, in comparison to conventional methods and the related safety measures, costs and delays.

Rotatable and maneuverable, it is especially suitable for confined applications in mining and shaft sinking as well as for driving cross-cuts in tunnel construction, since it is possible to work in any position within the working radius and also overhead, and this at any time while other work continues in parallel. The rock is not pulverized by the splitting technique. The cohesion of the material remains given and the production of larger split pieces guarantee you with more volume per borehole highest productivity under safe conditions.

The fixed Rock Splitter is attached directly to the carrier via the mounting plate and its alignment is not influenced by gravity.