Products | Rock and Concrete Splitters | C10S

Darda

Rock and Concrete

Splitters – the original

Can be used independently everywhere

Powerful in seconds

Low vibration and dust, almost noiseless

Economical and safe

Precise measurement can be controlled at any time

Robust and light

Options

and Accessories

Special lubricant

Lubrication of the pressure surfaces of the wedge and the counter wedges guarantee maximum utilization of splitting force and reduction of wear. Water resistant.

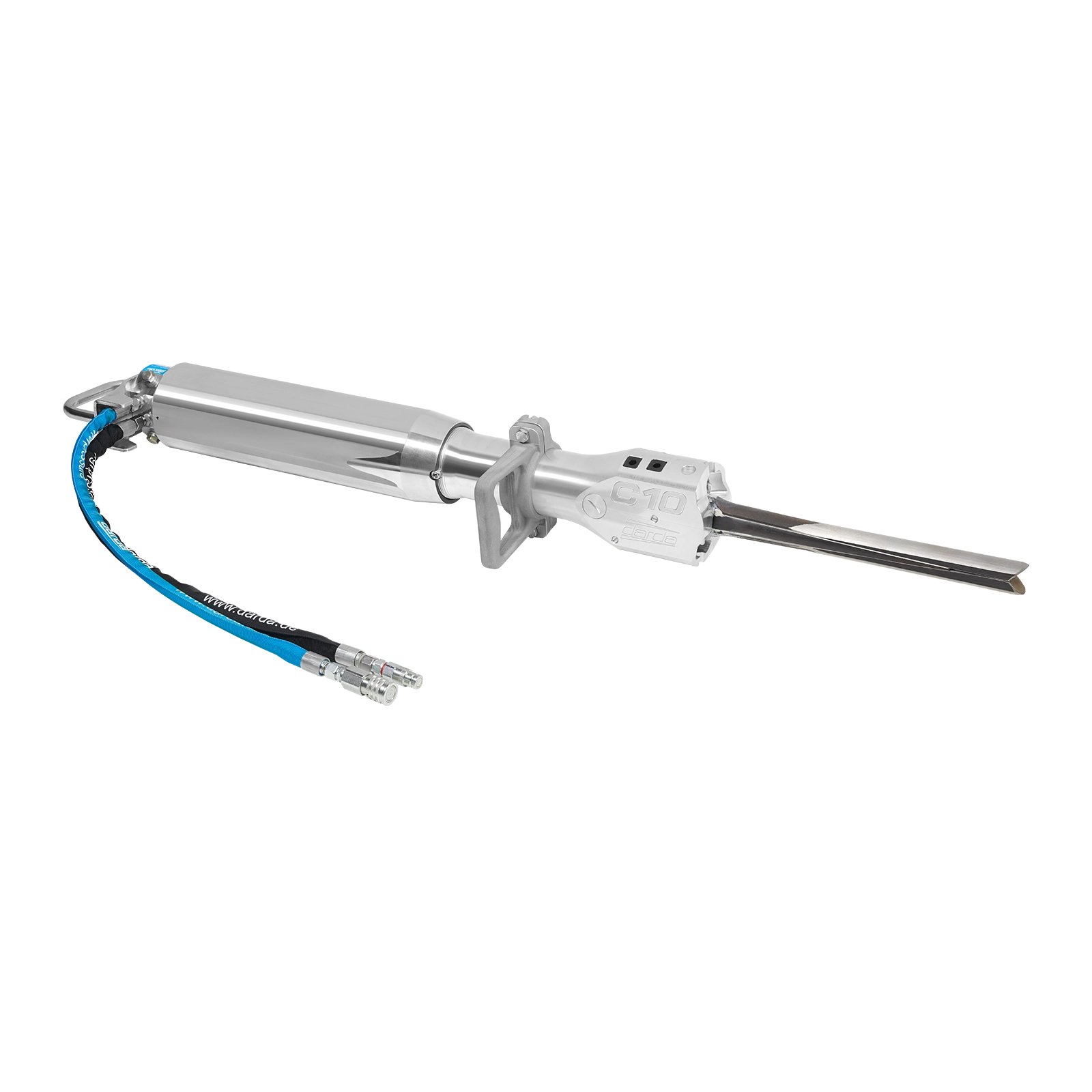

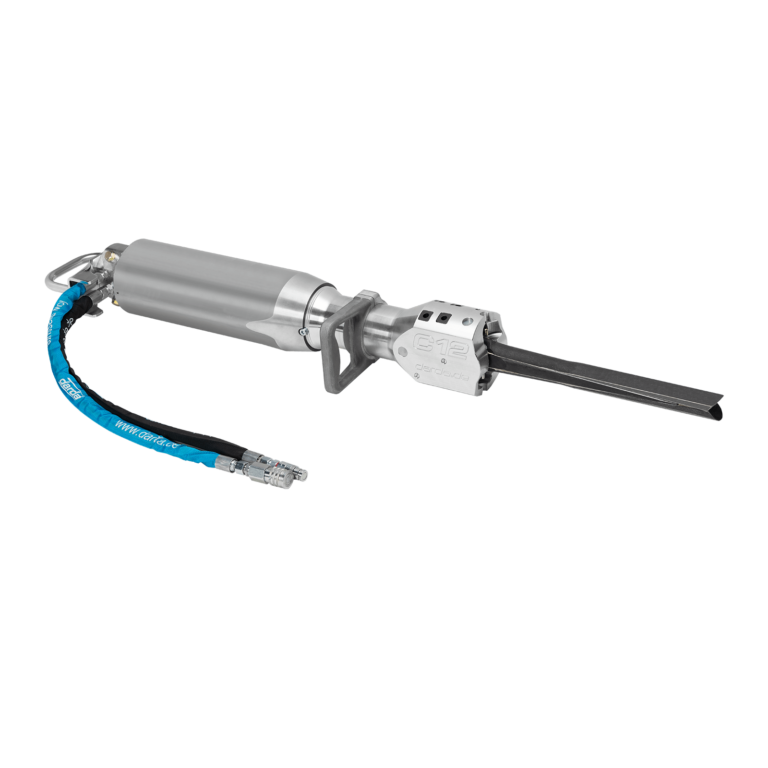

C10S – the accurate splitter for

natural stone quarrying

Taking advantage of the low tensile strength of rock and concrete, the hydraulic splitting cylinders enable controlled, quiet and cost-effective demolition from the inside!

Our cylinder model specially designed for natural stone quarrying has been constructed precisely for the properties required there. Thanks to its high splitting force, the C10S splitting cylinder breaks all types of natural stone very precisely and is particularly suitable for block extraction.

A reduced diameter of the splitting insert enables material-saving work. Particularly in this area of the natural stone industry, the even distribution of force when using several C10S splitting cylinders in series can achieve a very good splitting result. The C10S is ideal for use as a sliding cylinder for blocks that are stuck together, so-called “burnt” blocks. The splitting method does not cause hairline cracks in the rock, which can make the material unusable.

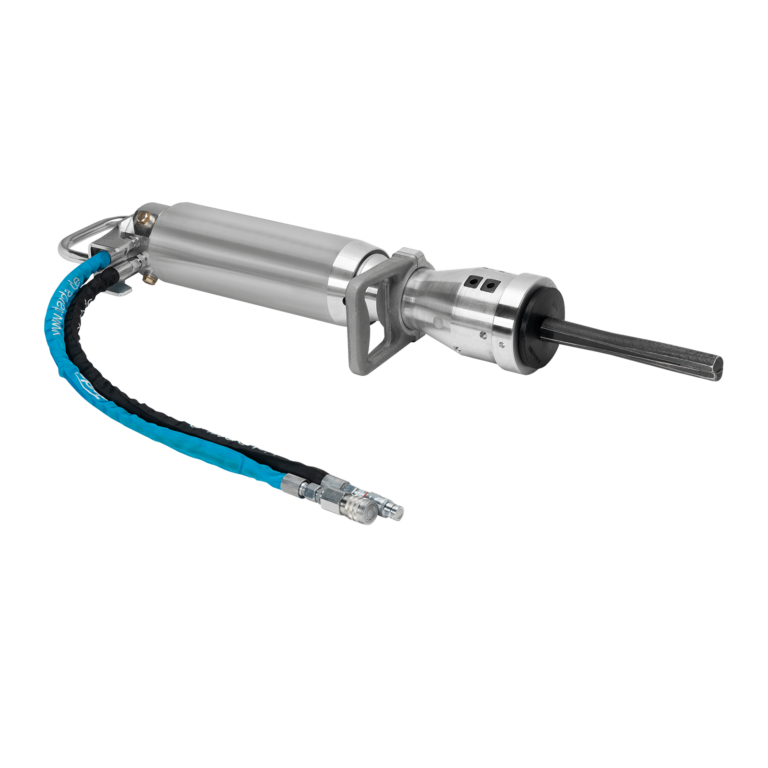

The handy stone and concrete splitting cylinder has an enormous power-to-weight ratio. One person can work in any position and even under water, while other work continues in parallel: Low noise, without vibrations and flying stones.

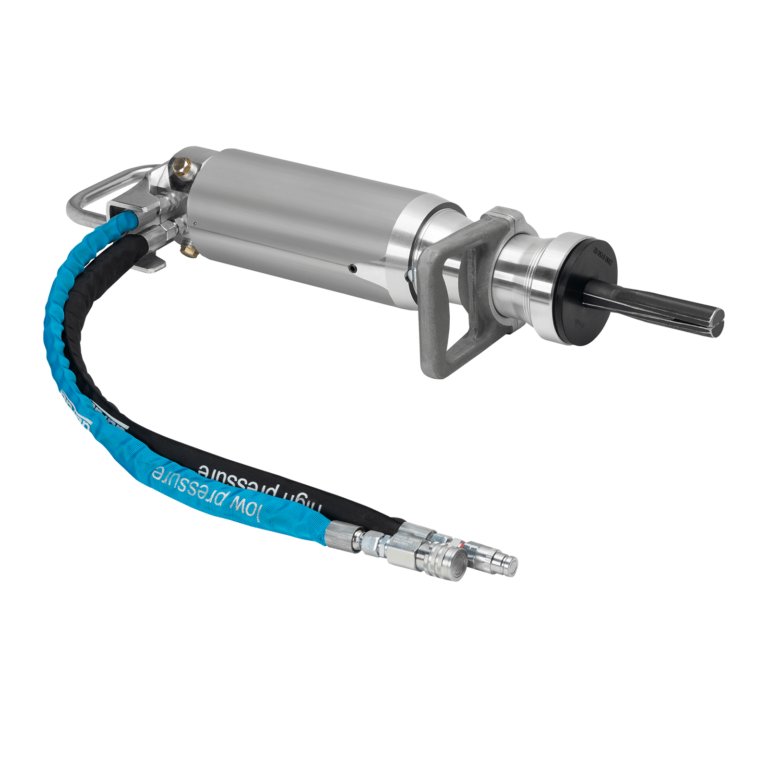

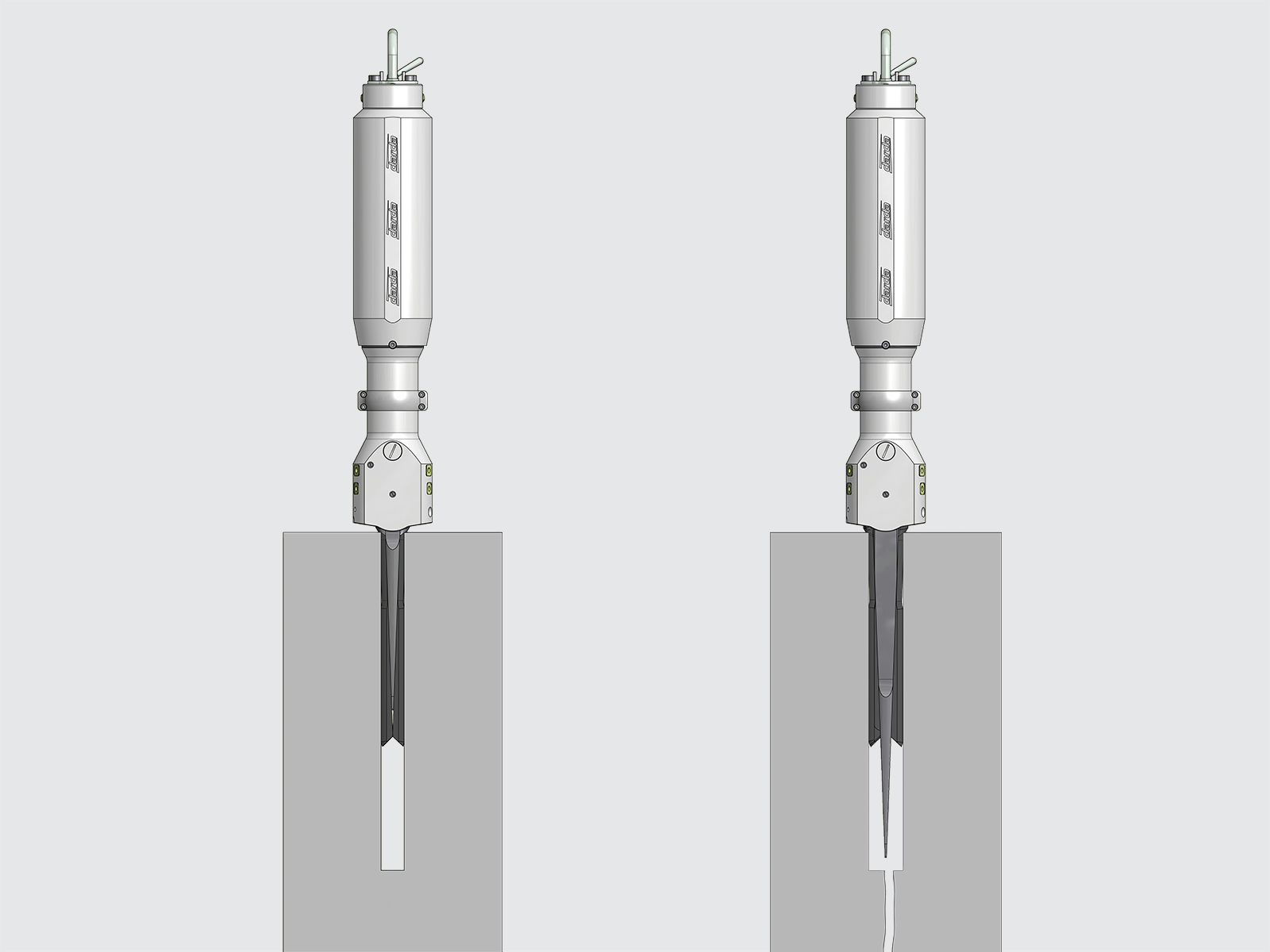

Functional principle

of the Hydraulic

Rock and Concrete

Splitters

Conventional mechanical methods destroy the structure of the material by applying external force. Rock and concrete, however, can withstand very large compressive forces from the outside. In comparison, the resistance to a force acting from the inside out is relatively low. The development of the Darda Rock and Concrete Splitter was based on this fact.

Safe wedge

principle

First, a hole of the appropriate depth and diameter is drilled, into which the splitting insert of the splitting cylinder is then inserted and aligned to determine the splitting direction. With hydraulic pressure, the wedge pushes itself between the two counter wedges and presses them apart. The effective splitting force of up to 413 tons or 4048 kN destroys the structure of concrete and rock from the inside. A split is created in a matter of seconds. Thinner reinforcing bars in reinforced concrete tear off.

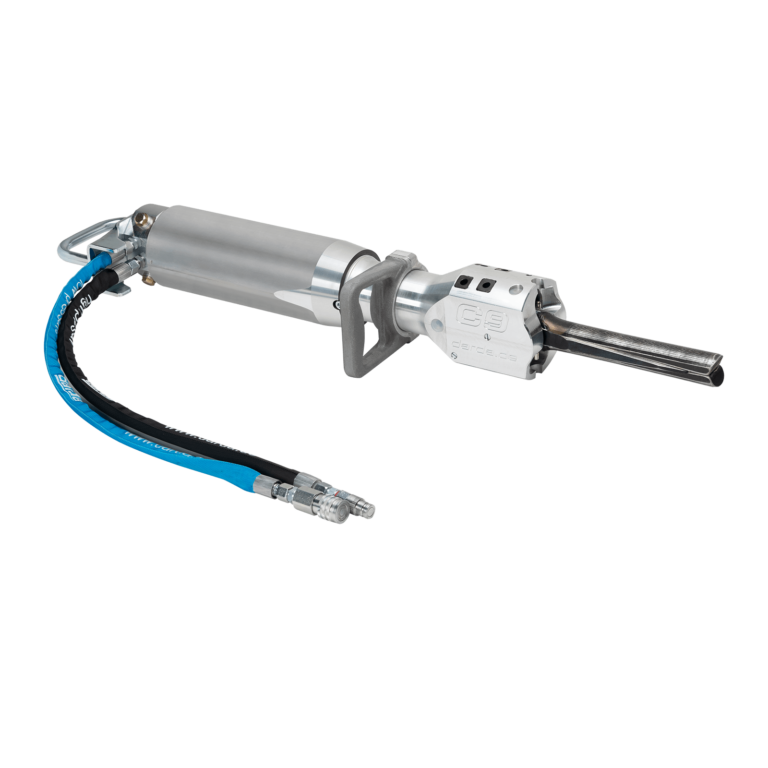

A complete

Splitting Unit

consists of three

components:

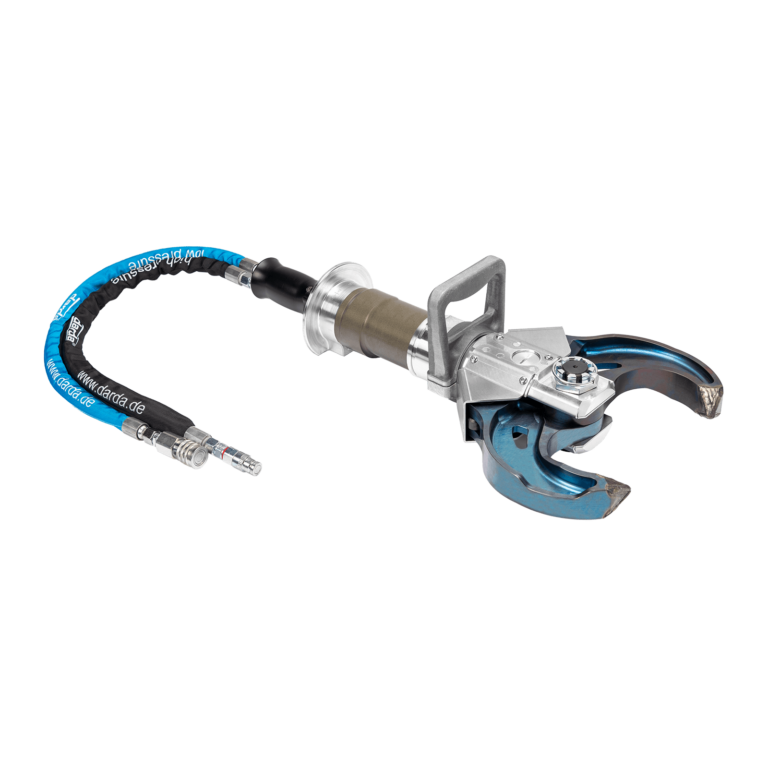

1. Hydraulic Splitter

2. Hydraulic Power Unit

3. Hydraulic hose set (high and low pressure)